How Supply Chain Disruptions Are Shaping the Auto Industry

The auto industry has always been one of the most rapidly evolving and competitive industries in the world. With the advancement of technology, increasing demand for sustainable and efficient vehicles, and changing consumer preferences, the auto industry has constantly been adapting to stay ahead of the curve. However, like most industries, the auto industry has recently faced significant challenges due to supply chain disruptions. From semiconductor shortages to pandemic-induced shutdowns, these disruptions have had a significant impact on the industry, shaping its current and future landscape. In this article, we will explore how supply chain disruptions are shaping the auto industry and the steps being taken to overcome these challenges.

The Impact of Supply Chain Disruptions on the Auto Industry

Supply chain disruptions are not a new concept for the auto industry. In recent years, natural disasters, trade wars, and political instability have all affected the industry’s supply chain. However, the extent and magnitude of the disruptions faced in the past year have been unprecedented. The ongoing COVID-19 pandemic has caused a domino effect, disrupting not only the production but also the supply of essential components, causing severe constraints for the industry.

One of the most significant challenges faced by the auto industry has been the shortage of semiconductors. These tiny but crucial components are used in almost every aspect of modern vehicles, including safety features, infotainment systems, and power management. The shortage of semiconductors has led to production delays and hiked up prices of vehicles, affecting the entire supply chain, from manufacturers to dealers and consumers.

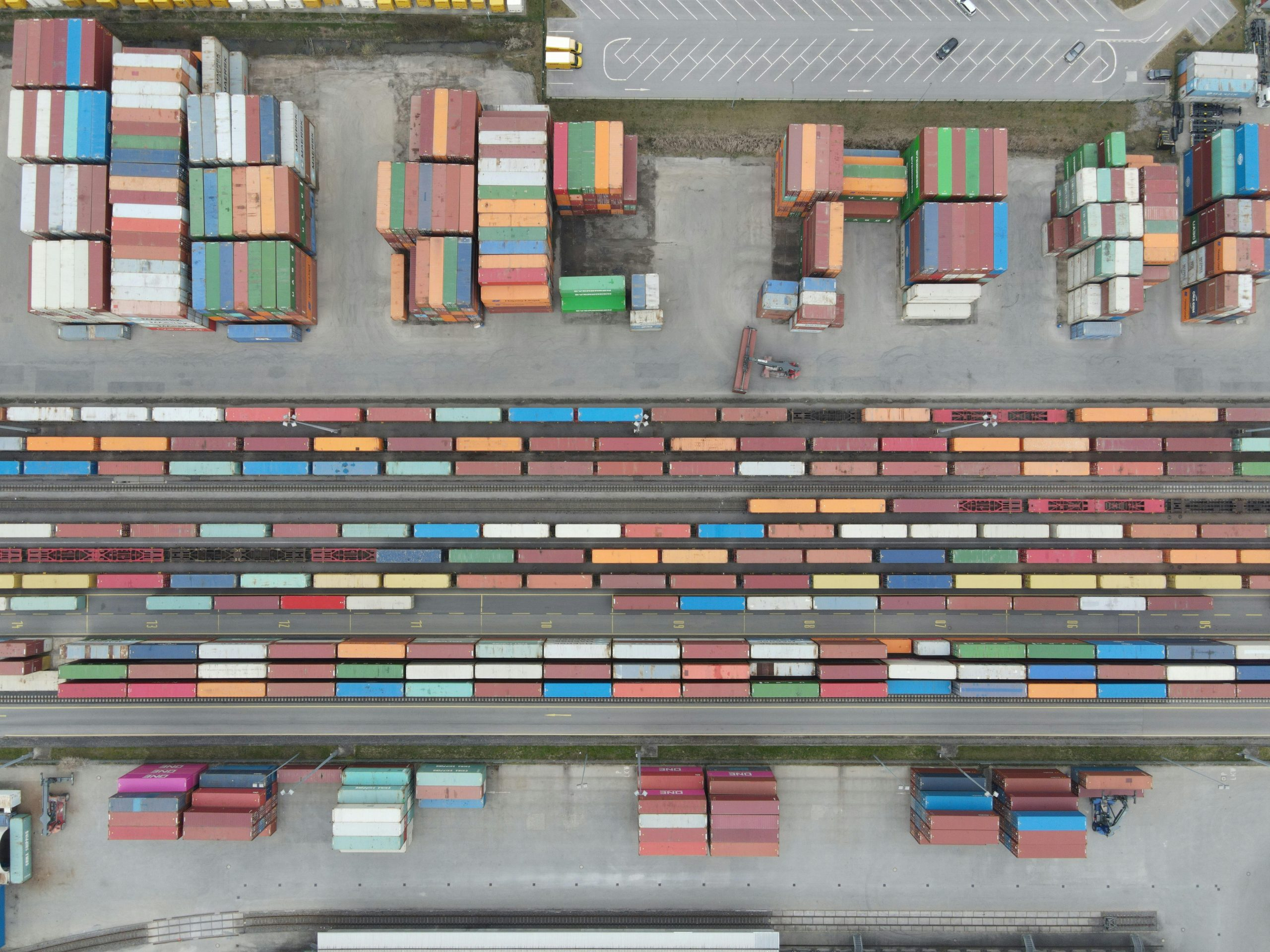

In addition to semiconductor shortages, the pandemic has also caused significant disruptions in the logistics and transportation industry. The lockdowns and travel restrictions imposed by various countries have significantly affected the transportation of raw materials and finished vehicles, leading to delays and increased costs.

The Changing Dynamics of the Auto Industry

Shift towards Electric and Autonomous Vehicles

The disruptions faced by the auto industry have forced manufacturers to rethink their strategies and shift towards more sustainable and technologically advanced vehicles. Electric and autonomous vehicles have been gaining momentum in recent years, and supply chain disruptions have accelerated this trend. With the ongoing push towards reducing carbon emissions and stricter environmental regulations, many countries have already announced their plans to phase out the production and sales of gasoline and diesel-powered vehicles in the near future.

Furthermore, the increasing demand for autonomous vehicles has also been a driving factor in this shift. With the advancements in technology and the potential for safer and more efficient transportation, autonomous vehicles are expected to become mainstream in the coming years. This shift to electric and autonomous vehicles opens up new opportunities for suppliers, manufacturers, and other players in the industry.

The Emergence of Diversified Supply Chain Strategies

The disruptions faced by the auto industry have highlighted the need for diversified supply chain strategies. The traditional approach of relying on a single supplier or region for critical components has proven to be risky in times of crisis. Many automakers are now looking to diversify their supply chain by sourcing from different suppliers and regions. This not only helps in mitigating the risk of disruptions but also allows for more flexibility and agility in the supply chain.

Moreover, the pandemic has also accelerated the trend of nearshoring, where automakers are shifting production to geographically closer regions. This helps in reducing transportation costs and lead times, while also supporting the local economy.

Overcoming Challenges and Moving Forward

The auto industry has been quick to respond to the supply chain disruptions and has taken several steps to mitigate their impact. As the demand for electric vehicles continues to grow, many automakers are investing in developing their own semiconductor manufacturing capabilities. This will help them have more control over the supply of critical components and reduce their reliance on external suppliers.

Collaboration and communication amongst industry players have also played a crucial role in overcoming the disruptions. Many suppliers and automakers have increased their communication and are working together to find solutions and ensure a steady supply of components.

Furthermore, the disruptions have highlighted the need for more data-driven and resilient supply chains. The use of advanced technologies like artificial intelligence, machine learning, and blockchain can help in predicting and mitigating supply chain disruptions, ensuring a more efficient and reliable supply chain in the future.

Conclusion

The auto industry has faced unprecedented challenges due to supply chain disruptions in the past year. However, these challenges have also brought about significant changes and opportunities. The shift towards electric and autonomous vehicles, adaptation of diversified and resilient supply chain strategies, and increased collaboration among industry players are all positive developments shaping the future of the auto industry. As the industry continues to evolve and adapt to the changing landscape, it will emerge stronger and more resilient than ever before.